Factory pheej yig Kub Thermal Exhaust Duct Fabric Expansion Joints

Peb nyob nrog peb lub tuam txhab tus ntsuj plig ntawm "Quality, Performance, Innovation and Integrity". Peb lub hom phiaj los tsim kom muaj txiaj ntsig ntau rau peb cov neeg siv khoom nrog peb cov peev txheej ntau, cov cuab yeej siv siab heev, cov neeg ua haujlwm paub txog thiab cov kev daws teeb meem zoo tshaj plaws rau Hoobkas Pheej Yig Kub Thermal Exhaust Fabric Expansion Joints, Zoo siab txais tos koj qhov kev tshawb nrhiav thiab txhua yam koj nug, ua tsaug vam tias peb tuaj yeem muaj sijhawm los koom tes nrog koj thiab peb yuav txhim kho lub tuam txhab kev sib yuav nrog koj.

Peb nyob nrog peb lub tuam txhab tus ntsuj plig ntawm "Quality, Performance, Innovation and Integrity". Peb lub hom phiaj los tsim kom muaj txiaj ntsig ntau rau peb cov neeg siv khoom nrog peb cov peev txheej ntau, cov tshuab siab heev, cov neeg ua haujlwm paub txog thiab cov kev daws teeb meem zoo rauTuam Tshoj Exhaust Duct Fabric Expansion Joints thiab Thermal Expansion Joints, Peb tau tsim muaj kev sib raug zoo thiab kev sib koom tes ntev nrog ntau lub tuam txhab hauv kev lag luam txawv teb chaws. Tam sim ntawd thiab tshwj xeeb tom qab-muag kev pab cuam muab los ntawm peb pab pawg neeg pab tswv yim tau zoo siab rau peb cov neeg yuav khoom. Hauv qhov tob Info thiab parameters los ntawm cov khoom muag tej zaum yuav raug xa tuaj rau koj kom paub meej meej. Cov qauv dawb tuaj yeem xa tuaj thiab lub tuam txhab tshawb xyuas rau peb lub tuam txhab. n Portugal rau kev sib tham yog txais tos tas li. Cia siab tias yuav tau txais cov lus nug ntaus koj thiab tsim kom muaj kev sib koom tes ua haujlwm ntev.

Daim ntawv thov ntawm Non-metal Fabric Expansion Joints

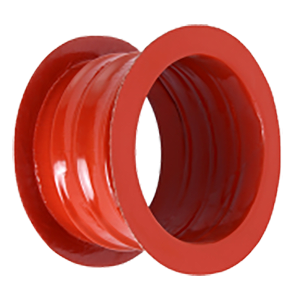

Corrugated Fabric Expansion Joints nrog rov qab yog hom tshiab ntawm cov hlau tsis muaj hlau txuas ntxiv. Qhov zoo tshaj plaws yog lub teeb yuag, supple, hermetic, siab ua hauj lwm kub, anti-corrosive, loj nyiaj them nqi thiab yooj yim installation. Lawv tsim nyog rau kev sib txuas yooj yim ntawm cov kiv cua sib txawv, ducts thiab pipework; tuaj yeem them nyiaj rau thermal deformation ntawm cov kav dej thiab tso tawm cov kav dej kev nyuaj siab; txo lossis ua kom tsis muaj zog ntawm kev co ntawm cov kav dej; thiab ua kom lub installation ntawm tag nrho cov system yooj yim dua.

Corrugated Fabric Expansion Joints yog txawv ntawm cov tsoos tsis yog hlau expansion sib koom ua ke. Nws yog ua los ntawm ib txheej lossis ntau txheej ntawm cov roj hmab thiab cov ntaub, laminated nyob rau hauv qhov kub thiab txias; lub revers yog tig thiab zoo li ib zaug nrog tshwj xeeb technics, uas yog txawv los ntawm cov craftwork rau tsim ib txwm ntaub expansion pob qij txha - gluing, xaws, npog thiab flange nias. Thiab cov technics tshwj xeeb ua rau peb cov pob qij txha expansion kov yeej cov tsoos expansion pob qij txha 'cov ntsiab lus tsis muaj zog xws li tsis ruaj khov laminated, tsis hermetic, leaking, hnyav, nyuaj rau installation thiab txij nkawm.

Corrugated Fabric Expansion Joints txuas mus rau flanges nrog nws tus kheej roj hmab txheej ntawm qhov thim rov qab, kev sib txuas yog hermetic heev; thiab tuaj yeem txhawb nqa max 2MPa ua haujlwm siab. Lub axial compression piv, radial thiab rotational hloov yog zoo dua li cov tsoos expansion pob qij txha. Peb Corrugated Fabric Expansion Joints yog qhov zoo tagnrho rau cov kiv cua cua, cov kav dej kom txo tau qhov system vibration, suab nrov thiab kev ntxhov siab. Lawv yog cov khoom zoo tshaj plaws uas koj yuav tsum muaj rau koj qhov system.

Peb siv ntau hom ntaub los ua cov pob qij txha nthuav dav raws li peb cov neeg siv khoom cov kev xav tau thiab kev siv ib puag ncig, xws li roj hmab silicon, fluorine roj hmab, Ethylene-Propylene-Diene Monomer (EPDM).

Pom zoo daim ntawv thov

● Txheej txheem kev lag luam

● Petrochemical kev lag luam

● Kev lag luam tshuaj

● Kev lag luam kws tshuaj

● Toxic, txaus ntshai, tshuaj lom neeg tshaj tawm

● Residue thiab khib nyiab incineration

● Calcination

● Kev txo qis

● Kev lag luam roj thiab roj

● Refining thev naus laus zis

● Fais fab nroj tsuag technology

● Pulp thiab ntawv kev lag luam

● Hlau ntau lawm thiab ua

● Kev lag luam cement

● Cov pa roj pa

● Boiler inlets thiab outlets

● Cov yeeb nkab nkag

● Cov kab txheej txheem

● Cov pawg

● Kev lag luam uas xav tau ntau dua

Qhov zoo

● Txo cov pa phem emissions

● Kev ua haujlwm nyab xeeb

● Kev txo qis hauv thawj lub zog siv

● Lub neej ua haujlwm ntev, hnav qis

● Predictable downtime

● Muaj raws li retrofit ntawm cov kab ke uas twb muaj lawm

● Zoo yoog raws

● Cov tshuaj tiv thaiv siab

● Txo qhov kub poob

● Cov tshuaj tiv thaiv tsawg kawg nkaus

※ Customized kom haum cov kev ua haujlwm tiag tiag thiab cov ntaub ntawv raws li kev thov.

| Npuag Khoom | Huab cua pov thawj muaj nuj nqi | Lub cev ua haujlwm | Tshuaj ua haujlwm | ua haujlwm kub | Tsis yog rau | |||||||||||||||||

| ozene ua | oxide | hnub ci | hluav taws xob | ntaub thickness | siab ntau | axial compression piv (%) | axial stretch ratio (%) | radial hloov (%) | haum rau kua dej | Kub H₂SO₄ | Kub H₂SO₄ | Kub HCL | Kub HCL | Tsis muaj dej ammonia | NaOH | NaOH | ua haujlwm qhov kub thiab txias | Max txuas ntxiv ua haujlwm kub | ib ntus max ua haujlwm kub | |||

| ntaub + roj foob txheej | Zoo siab | Tsis zoo siab | <50% | > 50% | <20% | > 20% | <20% | > 20% | ||||||||||||||

| EPDM roj hmab (EPDM) | zoo | zoo | zoo | zoo | 0.75 ~ 3.0 hli | max34.5 ua nqe 14.5 | max34.5 ua nqe 14.5 | 60% | 10-20% | 5-15% | corrosive gas organic kuab tshuaj dav dav gas | haum (zoo) | nruab nrab los yog pluag | nruab nrab | pluag | haum (zoo) | haum (zoo) | haum (zoo) | -50 ~ 148 ℃ | 148 ℃ | 176 ℃ | Aliphatic hydrocarbons Aromatic hydrocarbons |

| Silicone Roj Hmab (SL) | zoo | zoo | zoo | nruab nrab | 0.6 ~ 3.0 hli | max34.5 ua nqe 14.5 | max34.5 ua nqe 14.5 | 65% | 10% ~ 25% | 5% ~ 18% | dav dav gas | pluag | pluag | pluag | pluag | pluag | haum (zoo) | nruab nrab | -100 ~ 240 ℃ | 240 ℃ | 282 ℃ | Solvent roj kua qaub alkali |

| Chlorosulfonated polyethylene roj hmab (CSM / Hypalon) | zoo | zoo | zoo | zoo | 0.65 ~ 3.0 hli | max34.5 ua nqe 14.5 | max34.5 ua nqe 14.5 | 60% | 10-20% | 5-15% | corrosive gas organic kuab tshuaj dav dav gas | haum (zoo) | nruab nrab | nruab nrab | pluag | nruab nrab | haum (zoo) | haum (zoo) | -40 ~ 107 ℃ | 107 ℃ | 176 ℃ | Concentrated hydrogen chloride |

| Teflon yas (PTFE) | zoo | zoo | zoo | zoo | 0.35 ~ 3.0 hli | max34.5 ua nqe 14.5 | max34.5 ua nqe 14.5 | 40% | 5% ~ 8% | 5% ~ 10 | Feem ntau ntawm cov corrosive gas organic kuab tshuaj | haum (zoo) | haum (zoo) | haum (zoo) | haum (zoo) | haum (zoo) | haum (zoo) | haum (zoo) | -250 ~ 260 ℃ | 260 ℃ | 371 ℃ | Kev hnav tsis zoo |

| Fluororubber (FKM) / Viton | zoo | zoo | zoo | nruab nrab | 0.7 ~ 3.0 hli | max34.5 ua nqe 14.5 | max34.5 ua nqe 14.5 | 50% | 10-20% | 5-15% | corrosive gas organic kuab tshuaj dav dav gas | haum (zoo) | haum (zoo) | haum (zoo) | haum (zoo) dav dav | pluag | haum (zoo) | nruab nrab | -250 ~ 240 ℃ | 240 ℃ | 287 ℃ | ammonia |

Peb nyob nrog peb lub tuam txhab tus ntsuj plig ntawm "Quality, Performance, Innovation and Integrity". Peb lub hom phiaj los tsim kom muaj txiaj ntsig ntau rau peb cov neeg siv khoom nrog peb cov peev txheej ntau, cov cuab yeej siv siab heev, cov neeg ua haujlwm paub txog thiab cov kev daws teeb meem zoo tshaj plaws rau Hoobkas Pheej Yig Kub Thermal Exhaust Fabric Expansion Joints, Zoo siab txais tos koj qhov kev tshawb nrhiav thiab txhua yam koj nug, ua tsaug vam tias peb tuaj yeem muaj sijhawm los koom tes nrog koj thiab peb yuav txhim kho lub tuam txhab kev sib yuav nrog koj.

Hoobkas pheej yig kubTuam Tshoj Exhaust Duct Fabric Expansion Joints thiab Thermal Expansion Joints, Peb tau tsim muaj kev sib raug zoo thiab kev sib koom tes ntev nrog ntau lub tuam txhab hauv kev lag luam txawv teb chaws. Tam sim ntawd thiab tshwj xeeb tom qab-muag kev pab cuam muab los ntawm peb pab pawg neeg pab tswv yim tau zoo siab rau peb cov neeg yuav khoom. Hauv qhov tob Info thiab parameters los ntawm cov khoom muag tej zaum yuav raug xa tuaj rau koj kom paub meej meej. Cov qauv dawb tuaj yeem xa tuaj thiab lub tuam txhab tshawb xyuas rau peb lub tuam txhab. n Portugal rau kev sib tham yog txais tos tas li. Cia siab tias yuav tau txais cov lus nug ntaus koj thiab tsim kom muaj kev sib koom tes ua haujlwm ntev.